O que é um indicador de pesagem de gado e como ele funciona?

Dados precisos sobre o peso dos animais são essenciais para qualquer fazenda moderna — desde o gerenciamento das decisões diárias de alimentação até o acompanhamento do crescimento, o diagnóstico de problemas de saúde e a preparação dos animais para a venda. No centro de todo sistema de pesagem de animais está um dispositivo chamado balança indicador de pesagem de gado.

Mas o que exatamente ele faz e como funciona na sua fazenda?

Este guia explica tudo em termos simples e práticos.

1. O que é um indicador de pesagem para gado?

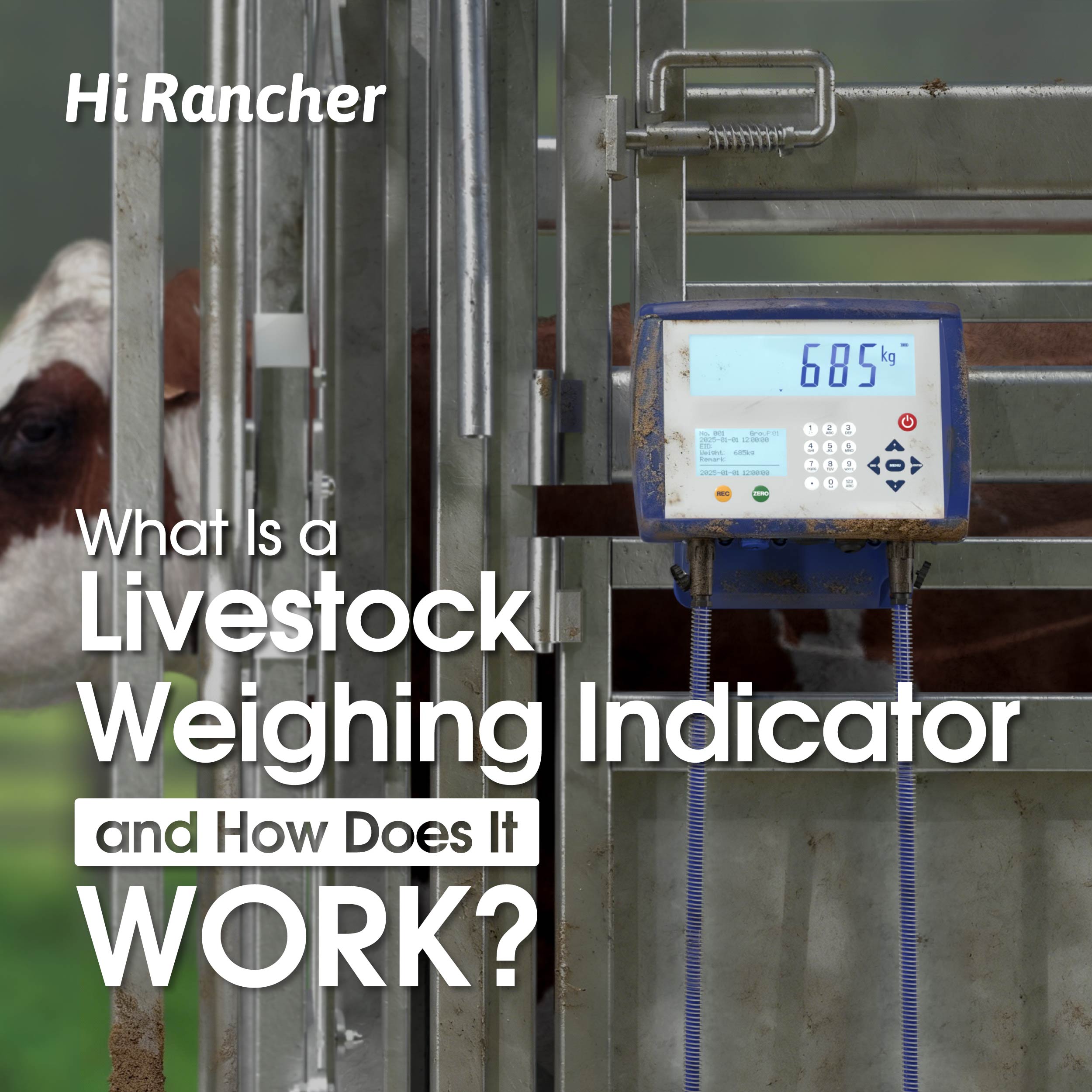

Um indicador de pesagem de gado é a unidade de controle que recebe sinais das barras de carga ou células de carga e os converte em um valor de peso estável e fácil de ler.

Ele funciona como o “cérebro” do sistema de pesagem e desempenha um papel fundamental em:

- estabilizando a leitura do peso

- filtrando o movimento animal

- Exibição de pesos em tempo real

- armazenar ou transmitir dados

- Conectando-se a leitores EID ou software de gestão agrícola.

Quer esteja a pesar gado bovino, ovino, caprino ou suíno, o indicador determina a rapidez, a precisão e a fiabilidade do seu processo de pesagem.

2. Por que os agricultores precisam de um indicador de pesagem para o gado?

O gado não fica parado, especialmente dentro de um brete ou em uma plataforma ao ar livre. Um indicador de qualidade garante a precisão da pesagem, mesmo quando o animal está se mexendo ou dando coices.

Os agricultores normalmente utilizam um indicador de pesagem para:

- Monitoramento do crescimento (verificando os ganhos diários ou semanais)

- decisões sobre eficiência alimentar

- Dosagem de medicamentos

- Avaliação da condição corporal e da reprodução

- Confirmação do peso de venda

- Registros de saúde e tratamento

Utilizar um indicador de pesagem de gado garante que todas as decisões relacionadas ao peso sejam baseadas em dados reais, e não em estimativas.

3. Como funciona um indicador de pesagem de gado?

O processo de trabalho é simples, mas altamente complexo:

Etapa 1 — As barras de carga detectam a força

Quando um animal fica em pé na plataforma ou dentro da rampa, barras de carga Meça a força descendente.

Etapa 2 — A força é convertida em sinais elétricos.

Cada barra de carga contém células de carga que geram um pequeno sinal elétrico proporcional ao peso.

Etapa 3 — O indicador recebe e filtra os dados

O indicador estabiliza o sinal utilizando:

- compensação de movimento

- filtragem digital

- rastreamento zero

- filtragem de vibração e choque

Isso é crucial porque os animais raramente ficam parados.

Etapa 4 — O indicador exibe um número estável.

Após o processamento dos dados, o indicador mostra uma leitura estável — mesmo que o animal esteja em movimento.

Etapa 5 — Armazenamento ou transmissão de dados opcionais

Os indicadores modernos também podem:

- registros de peso de armazenamento

- enviar dados para aplicativos móveis

- Exportar arquivos CSV

- pareamento com leitores EID

- Sincronizar com plataformas de gestão agrícola

Isso integra o sistema de pesagem a um fluxo de trabalho completo de monitoramento do gado.

4. Principais características a serem observadas em um indicador de pesagem de gado

Nem todos os indicadores são construídos da mesma forma. Os agricultores normalmente procuram por:

✔Estabilização rápida

Reduz o tempo de pesagem e aumenta a eficiência no manuseio.

✔ durabilidade externa

Carcaça robusta, design à prova d'água e botões resistentes aos raios UV são essenciais em condições agrícolas adversas.

✔ Tela grande e nítida

Os agricultores costumam pesar os animais ao ar livre, sob luz forte — a visibilidade é importante.

✔ Compatibilidade com barras de carga

A instalação plug-and-play economiza horas de tempo de configuração.

✔ Capacidade EID (opcional)

Para fazendas que utilizam etiquetas eletrônicas de identificação, a escolha de um indicador de pesagem de animais com integração de EID melhora significativamente a precisão dos registros.

✔ Opções de exportação de dados

A conectividade via USB, Bluetooth ou aplicativo ajuda a simplificar o registro de dados e o gerenciamento do rebanho.

5. Aplicações comuns de indicadores de pesagem de gado

Esses indicadores são utilizados em uma ampla gama de operações agrícolas, incluindo:

- currais para gado e balanças de corredor

- plataformas de confinamento

- balanças portáteis para ovelhas ou cabras

- sistemas de pesagem para corredores de suínos

- sistemas móveis de pesagem de reboques

- monitoramento do desempenho do rebanho leiteiro

- pesagem do tratamento veterinário

- verificações de peso pré-leilão

Independentemente da espécie ou configuração, o indicador garante que as leituras de peso sejam precisas e repetíveis.

6. Benefícios para agricultores e pecuaristas

Um indicador confiável de pesagem de gado ajuda as fazendas a atingirem:

➜ Maior produtividade

A pesagem mais rápida reduz o estresse tanto para os animais quanto para os tratadores.

➜ Melhores decisões de saúde

Pesagens precisas garantem a dosagem correta e a intervenção oportuna.

➜ Aumento da rentabilidade

Conhecer o peso exato da mercadoria à venda evita perdas na balança.

➜ Rastreabilidade aprimorada

Os indicadores compatíveis com EID registram dados de cada animal individualmente para fins de conformidade.

➜ Estabilidade do sistema a longo prazo

Os indicadores de qualidade resistem à chuva, às condições de congelamento e ao uso intenso na fazenda.

7. Escolhendo o indicador certo para sua operação

Ao selecionar um indicador de pesagem para gado, considere:

- quantos animais você pesa por dia

- se você precisa de capacidade EID

- seu ambiente (interno / externo / empoeirado / lamacento)

- o tipo de barras de carga ou plataforma que você usa

- seu software de gestão de rebanho

- Requisitos de alimentação (bateria / CA / recarregável)

Por exemplo:

- FOX Series → Uso diário na fazenda, simples e confiável

- FOX PRO → Indicador de escala pecuária com EID + funções avançadas de dados

- K7 → Opção econômica para pesagem básica

Escolher o modelo certo garante um fluxo de trabalho mais rápido e registros mais precisos.

Conclusão

Um indicador de pesagem de gado é uma das ferramentas mais valiosas na gestão animal moderna. Ela converte sinais brutos da barra de carga em pesos precisos e estáveis, ajudando os produtores a tomar decisões mais inteligentes sobre alimentação, tratamento e momento da venda.

Um bom indicador não é apenas um visor — é um controlador de pesagem completo, projetado para funcionar de forma confiável em condições agrícolas adversas.

Deseja melhorar o sistema de pesagem da sua fazenda?

A HiRancher fornece indicadores duráveis e comprovados em campo, projetados especificamente para operações pecuárias.

Quer você precise de pesagem básica ou de integração completa de dados EID, podemos ajudá-lo a escolher o sistema certo.

👉 Explore nossos indicadores de pesagem de gado.

👉 Solicite uma verificação de compatibilidade com suas barras de carga atuais.

👉 Solicite uma recomendação técnica gratuita.