Heavy-Duty Livestock Weigh Beams for Accurate Farm Weighing

Reliable weigh beams designed for cattle, sheep, and pig weighing systems

Built to deliver stable, repeatable weight readings in crushes, alleyways, and outdoor farm environments.

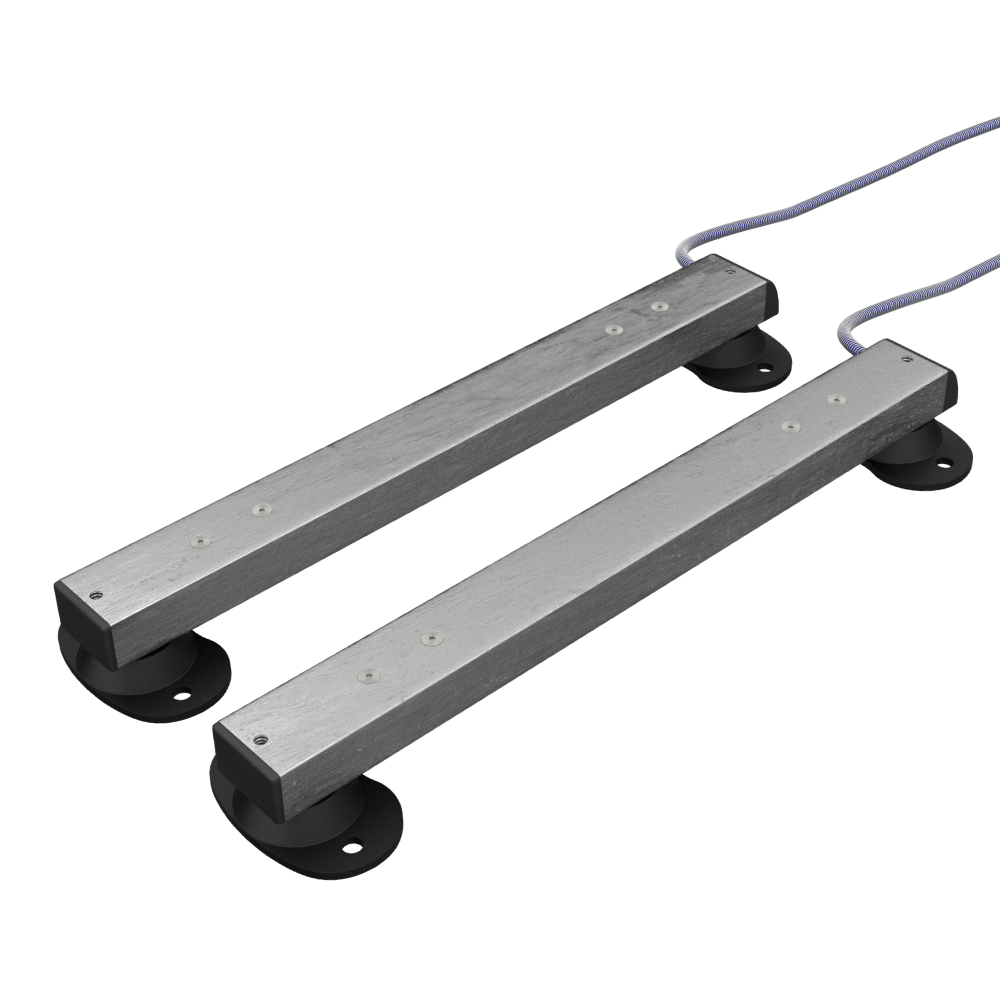

HiRancher ABH weigh beams are engineered specifically for livestock weighing, where animal movement, impact load, and harsh conditions are unavoidable. Whether installed under a cattle crush, raceway, or weighing platform, they provide dependable performance for daily farm operations.

✔ Designed for livestock movement and impact

✔ IP-rated protection for outdoor and muddy yards

✔ Compatible with digital weighing indicators and EID systems

Our ABH livestock weigh beams are suitable if you need:

If your operation involves regular livestock handling and weight monitoring, this weigh beam is designed for your setup.

👉 Not sure? Send us your setup details for confirmation

Installed beneath manual or hydraulic cattle crushes, ABH weigh beams deliver consistent results even when animals shift or apply uneven loads.

Ideal for race-based weighing systems where animals move quickly. The reinforced beam structure minimizes errors caused by side loading and impact.

Built for open yards exposed to rain, mud, and manure. Suitable for both permanent installations and mobile weighing platforms.

Compact and stable enough for smaller livestock, ensuring accurate data collection for growth tracking and management decisions.

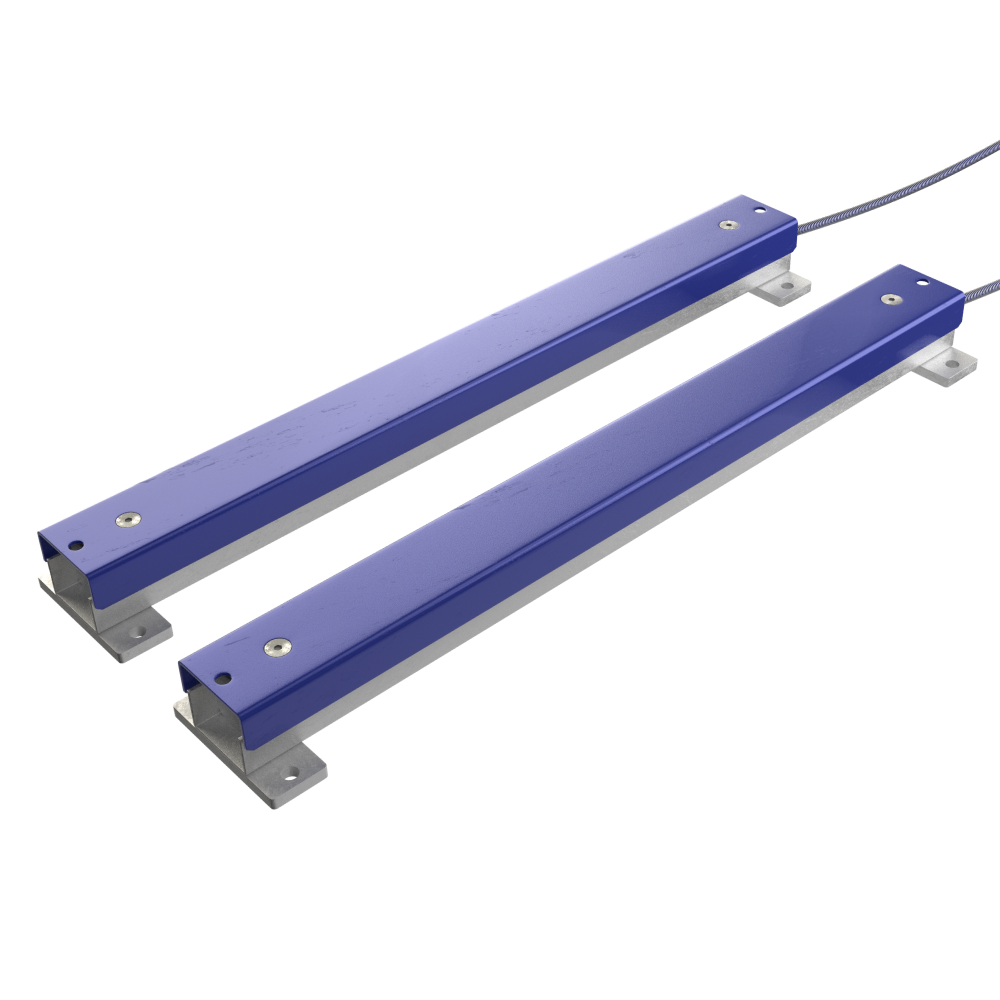

Unlike industrial weigh beams, ABH weigh beams are developed specifically for livestock behavior:

This ensures consistent weight data you can trust for herd management and traceability.

ABH weigh beams integrate seamlessly with:

They can be supplied as part of a complete livestock weighing solution, including indicators, EID readers, and data management support.

👉 Ask about complete weighing system packages

Designed to reduce setup time and long-term maintenance effort.

Yes, the powder-coated carbon steel provides good durability in farm environments. For high-humidity or coastal areas, hot dip galvanized ABT is also available.

Minimal. Just keep the bars clean and dry after use. Check cables for wear, and store indoors if unused for long periods. No frequent recalibration is needed thanks to the internal factory settings.

Weigh beams are more flexible, portable, and cost-effective. You can use them in various setups, under chutes, crates, platforms, and reposition them easily, which is ideal for livestock farming.

Choosing the correct weigh beam depends on animal type, capacity, installation method, and environment.

Tell us about your setup, and our engineers will recommend the most suitable beam configuration.

👉 Get a Weigh Beam Recommendation

👉 Request a Quote for Your Project

👉 Ask About Complete Livestock Weighing Systems

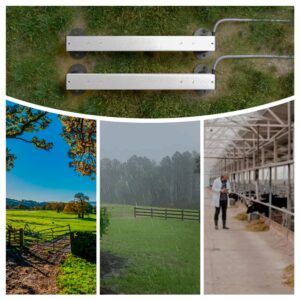

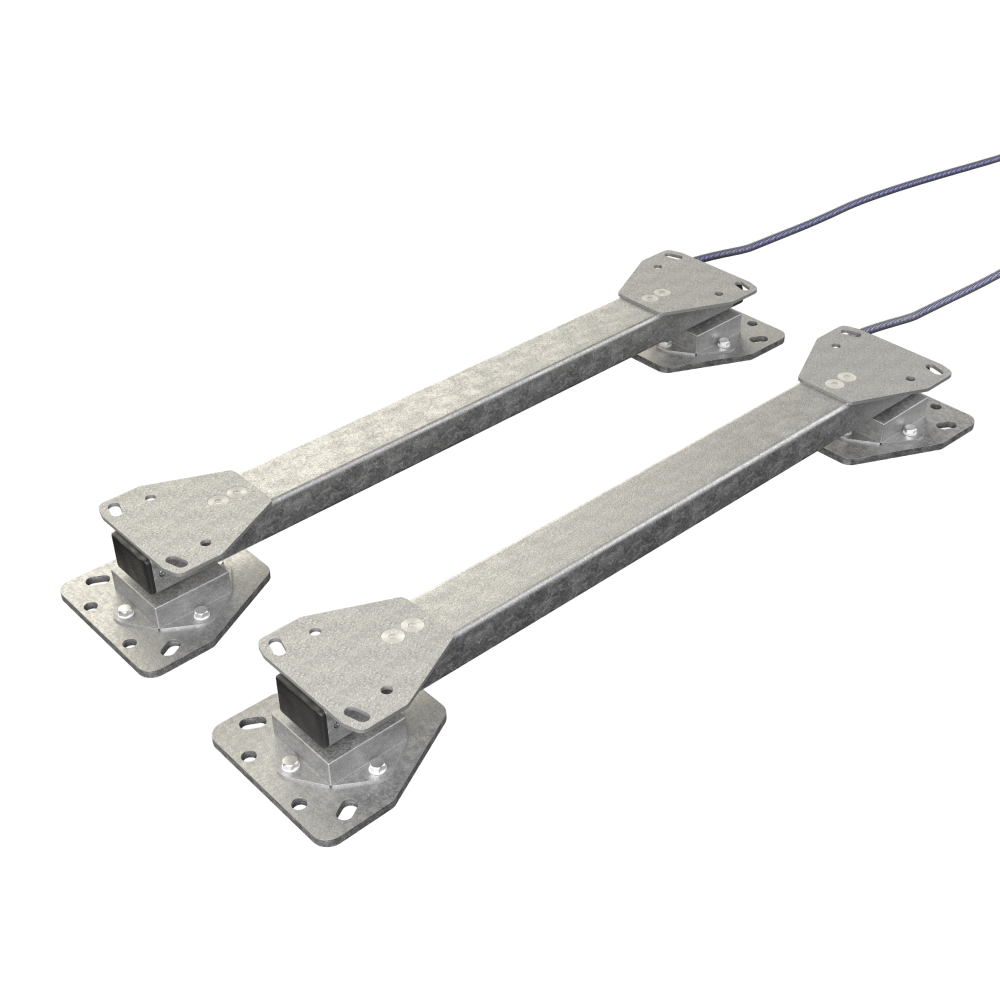

Tubular structure, designed for extreme environments. ABT livestock weigh bar feature hot-dip galvanized material and fully enclosed structure ensure long-term durability against moisture, mud, corrosion and temperature fluctuations.

The ABT outdoor weighing load bars are purpose-designed for farmers, contractors and processors who need accurate weighing in wet, muddy or corrosive environments. With a fully enclosed tubular housing, stainless cable protection and options up to 5,000 kg capacity, ABT bars deliver dependable readings in coastal farms, open yards, mobile trailers and slaughterhouse settings.As a trusted livestock load bars manufacturer, we ensure each unit is engineered for durability, precision, and long-term reliability under the toughest agricultural conditions.

No. Both models have the same accuracy and weighing performance. The key difference is in durability and environmental resistance.

The livestock weigh bar cable is shielded with a durable stainless steel spring cover to minimize wear and tear from animals or rough terrain.

Yes. The hot-dip galvanized tubular housing and sealed design are chosen specifically to resist salt spray and high-humidity corrosion.

In most cases ABT load bars are factory-matched to standard indicator inputs and do not require a full recalibration. We recommend a verification check with a known weight after installation.

Absolutely. The ABT design is compact and robust for trailer or portable platform weighing. Use the optional fixing holes or a secure clamp system for transport.

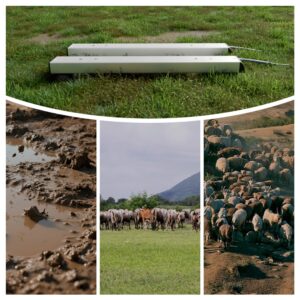

Designed to withstand the toughest livestock operations, AB5T 5t weigh bars feature reinforced feet for stable support under cattle crushes or animal crates. Their sealed tubular structure ensures long-lasting performance in extreme heat, cold, mud or dust.As a trusted livestock load bars manufacturer, we engineer every unit for superior durability, accuracy, and ease of use in demanding farm environments.

Simply position the bars parallel under the crush base, using the pre-drilled mounting holes for secure attachment if necessary.

Yes. Their rugged construction and sealed design make them perfect for mobile weighing platforms or trailer use across rough terrain.

AB5T is compatible with most indicators, including HiRancher FOX, FOX PRO and K7. Provide your indicator model and we’ll verify wiring and protocol.

AB5T works with most standard weighing indicators and is commonly paired with farm indicators such as FOX, FOX PRO and K7. If you’re retrofitting an older indicator, send us the model number — we’ll confirm wiring and protocol before shipment to avoid integration surprises.

…

HiRancher is a professional livestock load bar manufacturer specializing in rugged, high-accuracy load bars designed for cattle, sheep, pigs, and other livestock weighing applications. Our load bars are engineered to perform reliably under real farm conditions—mud, moisture, heavy loads, and frequent handling—delivering stable weight data you can trust. From permanent installations to portable weighing setups, HiRancher load bars form the foundation of dependable livestock weighing systems worldwide.

Livestock load bars are the core weighing components installed beneath platforms, crushes, or alleyway scales. They convert the animal’s weight into precise electronic signals for the weighing indicator.

High-quality load bars are essential to:

As an experienced livestock load bar manufacturer, HiRancher focuses on both measurement accuracy and long-term durability.

HiRancher offers multiple load bar models to suit different animals, environments, and weighing structures.

Every HiRancher product is designed from the perspective of a real farm operator:

Our livestock load bars are widely used in:

Whether for daily farm management or commercial livestock operations, our load bars provide dependable weighing support.

Selecting the right manufacturer ensures long-term performance and fewer operational issues.

We don’t just supply load bars—we help build complete, reliable livestock weighing systems.

Browse our livestock load bar models below to find the best fit for your platform, cattle crush, or alleyway scale.

If you need assistance selecting capacity, size, or compatibility with your weighing indicator, our team is ready to help.

Contact HiRancher today to discuss your livestock weighing requirements or request a complete system solution.

Online 24/7 to answer any of your questions at any time. Please contact us!

Hirancher specializes in livestock weighing and management systems, helping livestock producers weigh smarter, more accurately, and improve farm efficiency.